A story of French returning to its former glory! part 2

Last November we started to work on a beautiful Hispano-Suiza H6B Coupé Chauffeur that was created by the J. Fernandez coachbuilder. I can finally say the car has been done, assembled, tested and oh boy, the engine works perfectly!

The engine suffered from both having spoiled cooling system together with cracked (or corroded) block resulting in leakage of cooling liquid into oil further spoiling the greasing capabilities of the engine. We did not invest time to search for cracks or holes where the leak occurred as it was meaningless. Nevertheless the result of the problems were totally worn out conrods bearing shells (with some even partially collapsed), scratched crankshaft, badly damaged main bearing shells and fried pistons with further damage on the liners. It was decided that the engine will be redone with partially new parts, partially renovated ones.

And here come the photos!

New cylinder block with pistons

Detail of new pistons

In the month the work began a new block with pistons and piston hinges arrived. We still had to wait for the crankshaft to be machined, the bearing shells on both crankcase and conrods to be made and of course for the manpower to have time!

The crankcase with all new main bearing shells, cleaned and ready for use

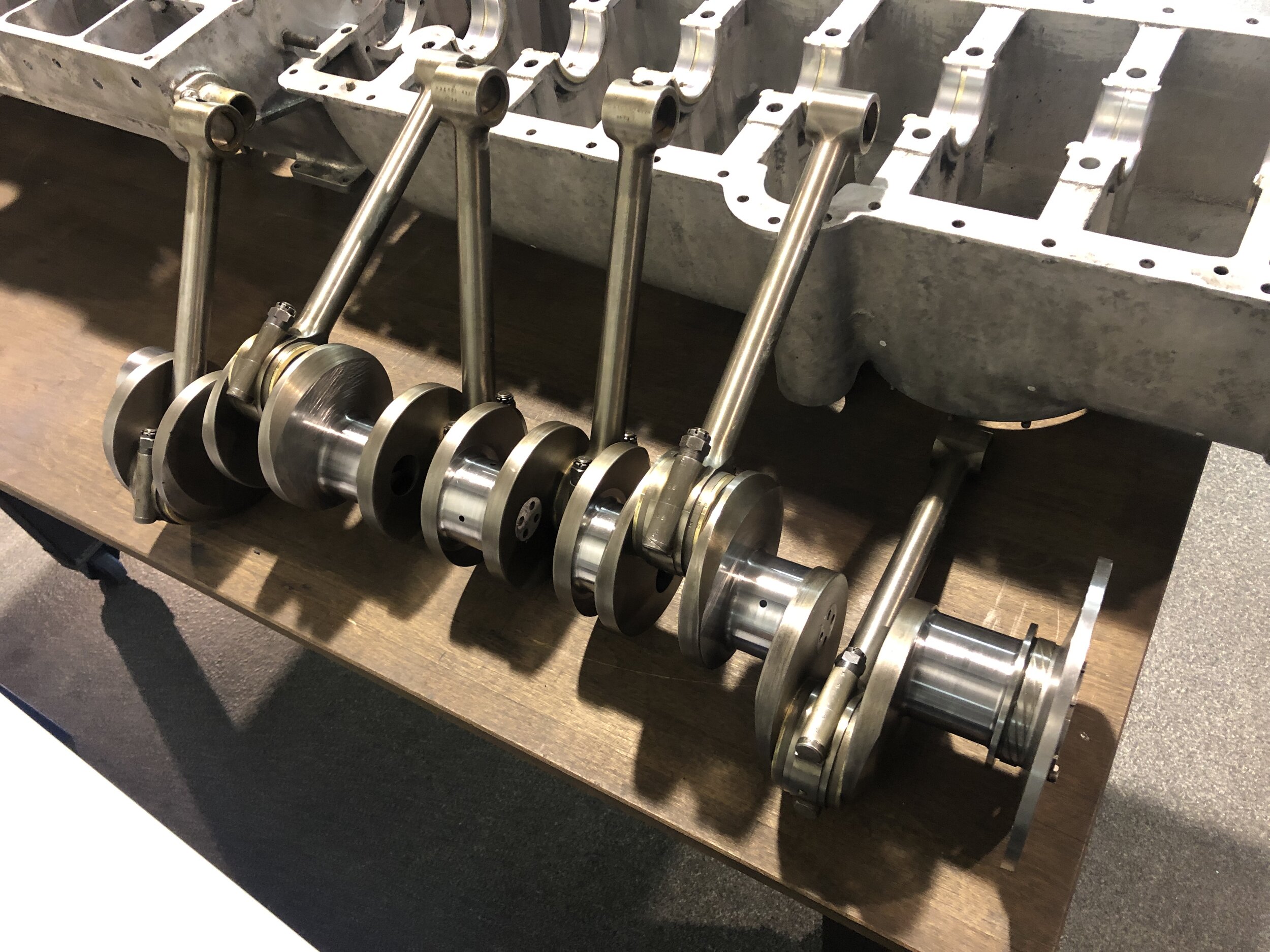

The crankshaft machined with the conrods already fitted on

The crankcase with new bearing shells together with the crankshaft and the conrods arrived during December. The old bearing shells were torn off both the conrods and the crankcase. The crankshaft needed only light machining on the main and rod journals, otherwise it was measured as perfect. Then the bearing shells on the crankcase were cast new and machined to fit perfectly the existing main journals. The bearing shells on the conrods were also cast new and then machined to fit the rod journals and the already measured piston hinges. So all the work proceeded with the original crankshaft in mind so all would align just fine. The conrods themselves were measured and considered to be in good condition. All was put together, and all lined up perfectly, one might say better than new.

Here only partially polished so far

When the crankcase was assembled, the polishing took place. The old crankcase needed some work as the aluminium looked really worn out and faded when the car was delivered. These H6 engines look fabulous when the aluminium parts are carefully polished and shiny and put in contrast with black paint of the block and cover. There was no debate over this, this engine was to be 100%.

A detail of polished crankcase

The bottom of the engine polished and assembled, ready for the block. Shinies!

Some parts were machined new, like these knees from the cooling system that sit on top of the engine right before the radiator

The side with edges polished and almost ready for painting

The front dynamo cover also during the process of becoming shiny

The process of having an old part polished is a labour intensive work that takes days to perfect. It took about a month of work of several people to have all the engine parts carefully restored to their designated state. But the results are amazing.

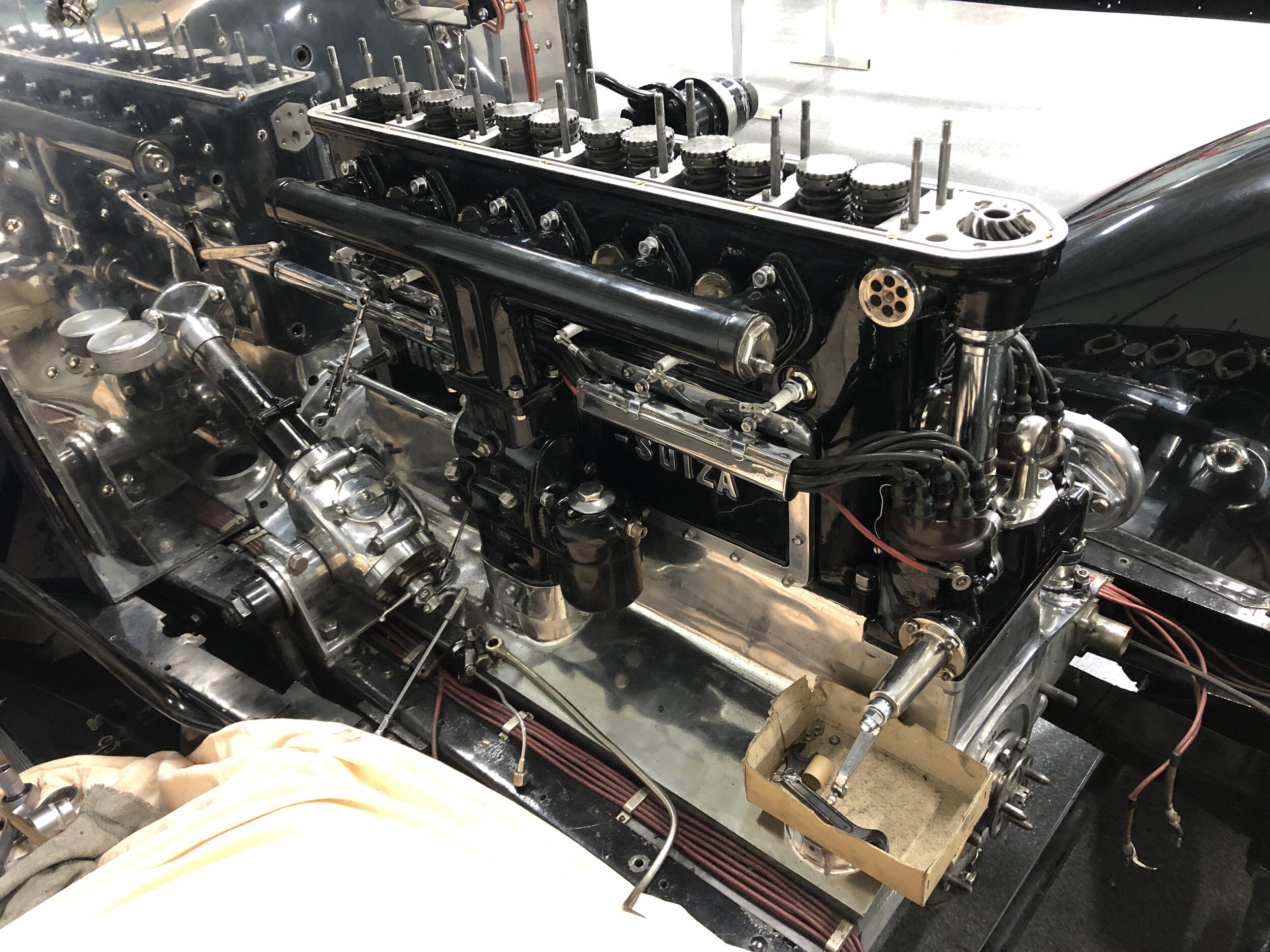

First glance at the engine already sitting in the chassis

Ready to have the camshaft put in place

And here we go!

We put in proper Millers Oils oil, more specifically the M50 Vintage. Instead of regular antifreeze liquid we use Evans Vintage Cool 180, so unlike with water-based coolants, we should not see any water-aluminium corrosion in the decades to come.

The whole package at its best!

The result is amazing. The old lady is again running with ease and the power is overwhelming, this car just pulls like it doesn’t mind! This Hispano-Suiza will be put in a very well maintained garage with stable temperature and humidity. This is exactly the love that every collector’s car should get. Perfecting its state and being stored properly.

It should be noted that the gearbox and clutch were all fine so there was no need to work on those. Only the engine was rebuilt.

Thank you for reading, if you have any questions, do not hesitate to ask!